The pharmaceutical industry has witnessed significant advancements thanks to digital transformation. In this context, **Homitex** has developed an intelligent system to automate the production processes at a pharmaceutical plant. The goal is to eliminate the traditional issues associated with paper-based documentation and human error, while achieving the highest levels of precision and quality in manufacturing.

Challenges Addressed by the System:

* Paper-based documentation was prone to damage, loss, or contamination.

* Difficulty in identifying the source and timing of errors.

* Delays in communication between staff and management.

* Time and resource waste due to the lack of real-time monitoring.

* Inability to meet time constraints, leading to material spoilage.

System Features:

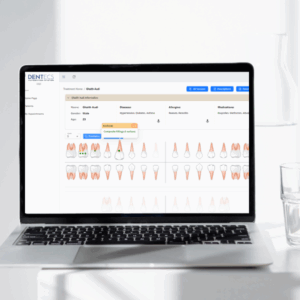

* Full automation of the production process—from issuing the production order to delivering the final product.

* Each employee has a dedicated interface with a built-in timer to track task execution time.

* Accurate determination of required weights based on product type and the active ingredient ratio.

* Reminder notifications to ensure adherence to optimal working conditions, such as room temperature during weighing.

* Strict enforcement of process order, preventing any step from being executed before the previous one is completed—minimizing errors.

* Replacement of paper with reviewable electronic records accessible at any time.

* Easy access to previous drug formulations with editing capabilities.

* Complete tracking of the production flow with precise error logging (who, when, and where).

* Timely notifications to remind employees of their tasks.

* Managerial oversight of the entire process from anywhere via system integration with communication platforms.

* Employee performance evaluation based on adherence to timing.

* Internal messaging to facilitate team communication.

* Automatically generated comprehensive reports detailing every step of the process.

This system not only enhances work efficiency and production quality, but also creates an interactive monitoring environment that promotes discipline and accountability. It provides management with a real-time, detailed view of all activities within the facility, reinforcing the reliability of the final pharmaceutical product.